Quality and advantages of building materials and construction

Building materials used in construction processes must have components, through which construction can resist all the natural factors to which it is exposed and which negatively affect them.

These materials should be characterized by their compliance with the required specifications and international quality standards. Among the most important construction materials used in construction operations are stones, woods, sand, cement, iron bars, and other types of other building materials.

Cement

| CEM I 42,5 R | PORTLAND COMPOSITE CEMENT | It is a hydraulic binder which is produced by grinding protland cement clinker, limestone and gypsum together. The limestone is used as a minor component andthe gypsum is used for regulation of the setting time. |

| CEM II / A-M (P-L) 42,5 R | PORTLAND COMPOSITE CEMENT | It is a hydraulic binder which is produced by grinding protland cement clinker,natural puzzolana (%12-20), lime stone and a certain amount of gypsum together. |

| CEM II / A-M (P-V) 42,5 R | PORTLAND COMPOSITE CEMENT | It is a hydraulic binder which is produced by grinding protland cement clinker,(%12-20) natural puzzolana, industrial puzzolana flyash, lime stone as a minor component and acertain amount of gypsum together. |

| CEM II / B-M (P-V) 42,5 N | PORTLAND COMPOSITE CEMENT (Kütahya) | It is a hydraulic binder which is produced by grinding protland cement clinker, (%21-35) natural puzzolana, industrial puzzolana flyash, limestone as a minor component and a certain amount of gypsum together |

| CEM IV / B (P-V) 32,5 N | POZZOLANIC CEMENT | It is a hydraulic binder which is produced by grinding protland cement clinker,(%36-55) natural puzzolana,industrial puzzolana flyash, limestone as a minor component and acertain amount of gypsum together. |

| CEM IV / B (P-V) 32,5 R | POZZOLANIC CEMENT (Kütahya) | It is a hydraulic binder which is produced by grinding protland cement clinker, (%36-55) natural puzzolana, industrial puzzolana fly ash, limestone as a minor component and a certain amount of gypsum together. |

Rebar

| TYPE | DIAMETER Ø *(MM) | LENGTH |

|---|---|---|

| A500C | 6, 8, 10, 12, 14, 16, 18, 20, 22, 24. 26, 30. 32, 36, 40 | 6-11,7 m |

| A500 | 6, 8, 10, 12, 14, 16, 18, 20, 22, 24. 26, 30. 32, 36, 40 | 6-11,7 m |

| A250 | 6, 8, 10, 12, 14, 16, 18, 20, 22, 24. 26, 30. 32, 36, 40 | 6-11,7 m |

Metal Products

| TYPE | Products |

|---|---|

| NON-FERROUS METALS | Nickel Cathode Zinc Ingots Lead Ingots Lead Anode Antimony Ingots Silicon Metal Aluminium Ingots Aluminium Titanium Boron Ingots, Sticks and Coils Aluminium Ingots Copper Anode Copper Arsenic |

| MINOR METALS | Cobalt Molybdenum |

| FERRO ALLOYS | Ferro Molybdenium Ferro Phosphorous Ferro Silicon Metallic Molybdenium Graphite Powder Carbon Ferro Manganese |

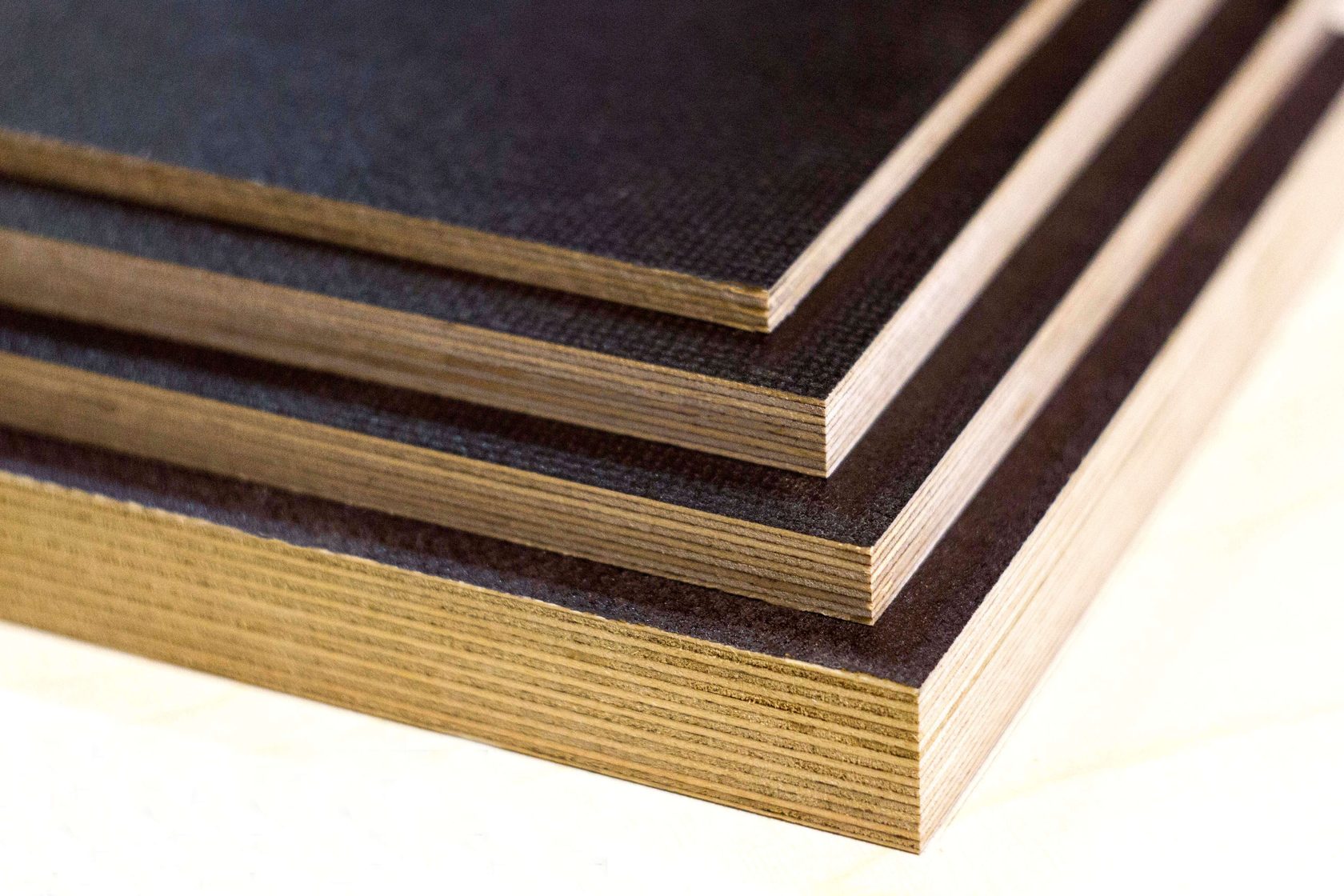

Plywood

| TYPE | Layer / Dimension | |

|---|---|---|

| Hexa Plywood | 3-16 2500 mm x 1250 mm | 2440 mm x 1220 mm | One surface of Hexagone Plywood is flat dark brown 120gr / m2, the other surface is coated with Hexa (hexagonal antislip) 240g / m2 phenolic film. |

| Wiremesh Plywood | 3-16 2500 mm x 1250 mm | 2440 mm x 1220 mm | Wiremesh Film is used for plywood, truck, van, small truck applications, truck trim, trailer flooring, buildings, small indoor applications. |

| Filmed Plywood | 3-16 2500 mm x 1250 mm | 2440 mm x 1220 mm | Filmed Plywood is a very good product with its smooth surface and durable hard structure. Due to its high quality construction material, it is preferred in construction-building sector. |

LINK-SEAL MODULAR SEAL

| TYPE | Sizes / Material | Fields of application |

|---|---|---|

| LINK-SEAL® C – galvanized LINK-SEAL® S 316 – stainless steel | LS 200 to LS 650 EPDM-Rubber; bolts: C galvanized / S 316 A 4-70 stainless steel; Shore A 50° ±5; pressure plates glass fiber reinforced polyamide | Use in normal atmosphere, water or humidity. Suitable for electrical isolation and cathodic corrosion protection. S 316: Resistant to water and against most inorganic (acids and alkalis) and organic substances |

| LINK-SEAL® BC – galvanized LINK-SEAL® BS 316 – stainless steel | LS 200 to LS 700 EPDM-Rubber; bolts: BC galvanized / BS 316 A 4-70 stainless steel; Shore A 40° ±5; pressure plates glass fiber reinforced polyamide | Particularly soft rubber, especially suitable for plastic pipes. Use in normal atmosphere, water or humidity. Suitable for electrical isolation and cathodic corrosion protection. S 316: Resistant to water and against most inorganic (acids and alkalis) and organic substances. |

| LINK-SEAL® OC – galvanized LINK-SEAL® OS 316 – stainless steel | LS 200 to LS 650 NITRIL-Rubber; bolts: OC galvanized / OS 316 A 4-70 stainless steel; Shore A 50° ±5; pressure plates glass fiber reinforced polyamide | Good resistance against oils; aromatic fuels; solvents; mineral oil-based products |

| LINK-SEAL® W – stainless steel | LS 200 to LS 650 EPDM-Rubber; bolts: A 4-70 stainless steel; Shore A 50° ±5; pressure plates glass fiber reinforced polyamide | Suitable for applications in the drinking water sector |

| LINK-SEAL® T – galvanized | LS 200-T to LS 575-T Silicone-Rubber; Shore A 50° ±5; bolts galvanized; pressure plates St 37 galvanized | Especially suitable for extreme temperatures. |